The chaulk free solution

We had a room with three heating-cabinets, that was sealed in with chaulk. This solution is in many cases fine, but these cabinets are taken out for inspection, service etc. a handfull of times a year.

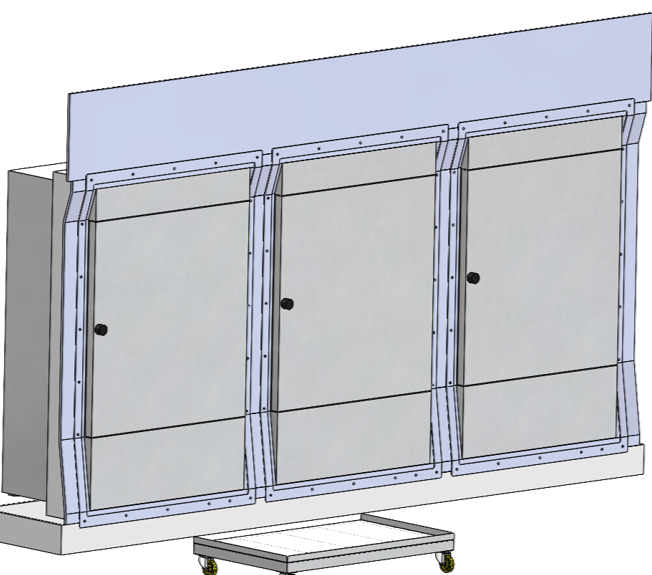

A chaulk free solution was needed. We ended up with a design in compact laminate and stainless steel.

The surrounding cabinet in compact laminate, and a steel frame on the individual heating-cabinets are designed to match each other, and then sealed off with a steel frame, that overlaps the both. On the backside of the overlapping frame there is pharma approved silicone band attached.

The overlapping frames can easely be deattached, and then the heating-cabinets can be serviced. without the mess and hussle of removing and remaking chaulk seals.

From the old installation

From the old installation

Mounting of the new installation

Final assembly

From the old installation

Mounting of the new installation

CAD-model